I’m thrilled to share my journey exploring Shark Coatings and epoxy, two popular flooring solutions that promise durability and style. My goal is to break down their features, weigh their strengths and weaknesses, and help you decide which is best for your space. From garages to restaurants, I’ve analyzed these coatings to uncover what makes them tick. This article offers a clear, engaging comparison, complete with a table, personal insights, and answers to common questions, ensuring you can confidently choose the right option for your needs.

Comparison Table: Shark Coatings Vs. Epoxy

| Feature | Shark Coatings | Epoxy |

|---|---|---|

| Durability | Highly durable, resists abrasions and impacts | Durable but prone to chipping and cracking |

| Cure Time | Fast-curing, ready in hours | Slower, takes days to fully cure |

| UV Resistance | Excellent, no yellowing | Poor, fades under sunlight |

| Maintenance | Low, easy to clean | Moderate, requires regular upkeep |

| Chemical Resistance | Superior, resists oils and solvents | Good but less resilient |

| Aesthetic Options | Wide range of colors and patterns | Limited compared to Shark Coatings |

| Cost | Higher initial cost, better long-term value | Lower initial cost, higher maintenance |

| Lifespan | 15 years (interior), 5 years (exterior) | 5-10 years, depending on use |

| Application Complexity | Professional installation recommended | DIY-friendly but complex for large areas |

My Experience With Shark Coatings

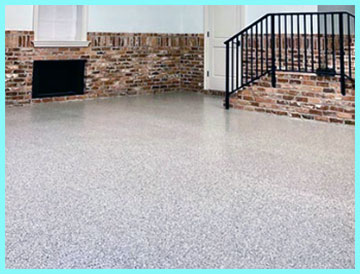

When I decided to upgrade my garage floor, I chose Shark Coatings after hearing about their durability and sleek look.

The installation team was professional, though the prep work took longer than expected—grinding the concrete to ensure a smooth bond felt like overkill at the time.

Once applied, the coating cured in just a few hours, and I was back to using my garage the same day.

The glossy finish and custom flake pattern turned my dull concrete into a showpiece, and I’ve since parked cars, dropped tools, and spilled oil without a single mark.

Cleaning is effortless; a quick mop handles everything. The only downside was the cost, which stung initially, but after two years, the floor still looks brand new, and I haven’t spent a dime on repairs.

Compared to friends’ epoxy floors, which already show wear, I’m convinced Shark Coatings were worth it. For outdoor spaces like my patio, the UV resistance has been a lifesaver, keeping colors vibrant despite constant sun exposure.

Read More: My Thoughts On Flooret Base Vs. Signature

Pros Of Shark Coatings

- Exceptional Durability: Shark Coatings, made from polyurea and polyaspartic materials, are built to last. They withstand heavy foot traffic, machinery, and impacts, making them ideal for high-traffic areas like restaurants or garages. I’ve seen them hold up in busy environments without a scratch, unlike other coatings that wear down quickly.

- Fast Cure Time: One of the standout features is how quickly Shark Coatings set. They cure in hours, not days, which means less downtime for your space. This was a game-changer for me when I needed a quick turnaround for a commercial project.

- UV Resistance: These coatings don’t yellow or fade under sunlight, making them perfect for outdoor spaces like patios or pool decks. I’ve noticed they maintain their vibrant look even after months of exposure to harsh UV rays.

- Low Maintenance: Cleaning is a breeze with Shark Coatings. Their non-porous surface resists stains, and a simple sweep or mop keeps them looking fresh. I’ve spent far less time scrubbing compared to other flooring options.

- Chemical and Temperature Resilience: Shark Coatings handle harsh chemicals like gasoline or chlorine without deteriorating. They also perform well in extreme temperatures, from freezing cold to scorching heat, which I found impressive in varied climates.

- Design Flexibility: With a variety of colors, patterns, and finishes, Shark Coatings offer endless customization. I’ve experimented with metallic finishes and bold patterns, and the results always feel modern and unique.

- Long-Term Value: Though the upfront cost is higher, their longevity and low maintenance make them cost-effective over time. I’ve calculated savings from reduced repairs and upkeep, which adds up significantly.

Cons Of Shark Coatings

- Higher Initial Cost: Shark Coatings can be pricier upfront compared to epoxy. I found the initial investment steep for smaller projects, though the long-term benefits often justify the cost.

- Professional Installation Recommended: The application process is complex and best left to experts. I tried a small DIY project once, and the results were uneven, requiring professional correction, which added to the expense.

- Limited Availability: Not all contractors offer Shark Coatings, as they require specialized training. I had to search extensively to find a reliable installer in my area, which was a hassle.

- Surface Preparation Demands: The concrete surface must be meticulously prepped for optimal adhesion. I learned the hard way that skipping steps like grinding or etching can lead to coating failure.

- Not Ideal for All Climates: While temperature-resistant, extreme humidity can affect curing. I noticed slight issues in a coastal project where moisture levels were high, requiring extra care during installation.

- Less Familiar to Consumers: Shark Coatings are less known than epoxy, so finding reliable information or reviews can be tough. I had to dig deep to understand their benefits fully, unlike the more common epoxy.

- Potential for Overhype: Some claims, like being “20x more durable,” feel exaggerated. While they outperform epoxy, I found the real-world difference closer to 2-3x in most scenarios, still impressive but not miraculous.

My Experience With Epoxy

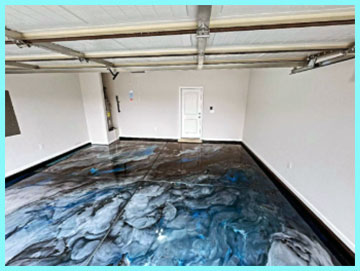

I first used epoxy for my basement floor, drawn by its affordability and DIY appeal. The application was straightforward but time-consuming—mixing the resin and hardener required precision, and the curing process took nearly a week. The result was a glossy, professional-looking floor that impressed me at first. However, after a year, I noticed scratches from moving furniture and slight yellowing near windows where sunlight hit. Cleaning was more involved than I’d hoped, as dirt got trapped in minor scratches. For indoor spaces with light traffic, epoxy worked well, but for my garage, where I later used Shark Coatings, epoxy wouldn’t have held up. I’ve also seen epoxy fail in friends’ outdoor spaces, fading quickly under UV exposure. It’s a solid choice for budget projects, but I learned it’s not a long-term solution for heavy-duty areas.

Pros Of Epoxy

- Cost-Effective Upfront: Epoxy is generally cheaper to install than Shark Coatings, making it appealing for budget-conscious projects. I’ve used it for smaller spaces where cost was a major factor, and it delivered solid value.

- DIY-Friendly: Epoxy kits are widely available, and with some effort, you can apply them yourself. I tackled a basement floor with a friend, and while it wasn’t perfect, the process was manageable for amateurs.

- Strong Adhesion: Epoxy bonds well to concrete, creating a seamless, glossy finish. I’ve seen it transform worn-out floors into polished surfaces that look professional when done right.

- Chemical Resistance: It holds up well against spills like oil or mild chemicals, which is great for garages or workshops. I’ve spilled paint thinner on an epoxy floor, and it wiped off without issue.

- Versatile Applications: Epoxy works on floors, walls, and even machinery, offering flexibility. I’ve used it in both residential and commercial settings, appreciating its adaptability.

- Widely Available: You can find epoxy products and installers almost anywhere. I had no trouble sourcing materials or finding contractors familiar with epoxy, unlike Shark Coatings.

- Aesthetic Appeal: Epoxy offers a sleek, modern look with options for metallic or flake finishes. I’ve created stunning floors with epoxy that rivaled more expensive coatings in appearance.

Cons Of Epoxy

- Prone to Damage: Epoxy chips, cracks, and peels over time, especially under heavy use. I noticed scratches on my epoxy-coated workshop floor after just a year of moderate traffic.

- Slow Cure Time: It can take days to fully cure, which disrupts your space. I once had to block off a garage for a week, which was inconvenient for my family.

- UV Sensitivity: Epoxy fades and yellows in sunlight, making it unsuitable for outdoor use. My patio epoxy floor lost its shine within months, forcing me to replace it.

- High Maintenance: Epoxy requires regular cleaning and occasional touch-ups to maintain its look. I spent more time scrubbing stains than I expected, especially in high-traffic areas.

- Limited Design Options: Compared to Shark Coatings, epoxy has fewer colors and patterns. I found it harder to achieve a truly unique look without significant customization costs.

- Vulnerable to Extreme Conditions: Epoxy struggles with harsh chemicals or temperature swings. I saw an epoxy floor in a restaurant kitchen stain permanently after a solvent spill.

- Shorter Lifespan: Even with proper care, epoxy typically lasts 5-10 years, less than Shark Coatings. I’ve had to recoat epoxy floors sooner than expected, adding to long-term costs.

Comparison With Other Brands

- Shark Coatings vs. Polyurea: Shark Coatings are a blend of polyurea and polyaspartic, offering similar benefits to pure polyurea, like fast curing and durability. However, I found Shark Coatings slightly more versatile in design options, with better adhesion in humid conditions compared to some polyurea brands I’ve tried.

- Shark Coatings vs. Urethane: Urethane coatings are tough but less UV-resistant than Shark Coatings. I’ve seen urethane floors crack under extreme temperatures, while Shark Coatings held up better in similar conditions.

- Epoxy vs. Acrylic Paints: Acrylic paints are cheaper but far less durable than epoxy. I used acrylic for a temporary project, and it peeled within months, whereas epoxy lasted years, though still not as long as Shark Coatings.

- Epoxy vs. Tile: Tile is durable but requires grout maintenance, which I found tedious compared to epoxy’s seamless finish. However, epoxy’s susceptibility to UV damage makes tile a better outdoor choice in my experience.

- Shark Coatings vs. Polyaspartic Alone: Pure polyaspartic coatings share Shark Coatings’ fast cure time and UV resistance but can be less impact-resistant. I noticed Shark Coatings’ blend offers a slight edge in heavy-duty settings like industrial floors.

- Epoxy vs. Concrete Sealers: Concrete sealers are a budget option but lack epoxy’s aesthetic appeal and chemical resistance. I’ve used sealers for basic protection, but epoxy provided a more polished look and better performance.

- Shark Coatings vs. Traditional Coatings: Traditional coatings like oil-based paints can’t match Shark Coatings’ durability or ease of maintenance. I’ve seen traditional coatings fade and chip quickly, while Shark Coatings stayed pristine.

Also Read: My Thoughts On Newton Laminate Flooring

Frequently Asked Questions (FAQ)

Shark Coating is highly durable, UV-resistant, and low-maintenance, making it excellent for high-traffic or outdoor areas. It outperforms epoxy in longevity and ease of care.

Shark Coatings often surpass epoxy due to faster curing, better UV resistance, and superior durability, especially for demanding environments like restaurants or garages.

With proper installation, Shark Coatings last up to 15 years indoors and 5 years outdoors, significantly outlasting epoxy in most cases.

Shark Coating is a blend of polyurea and polyaspartic materials, offering enhanced chemical and temperature resistance compared to epoxy’s thermosetting resin.

Conclusion

You’re probably wondering which coating is right for your space, and I get it—choosing between Shark Coatings and epoxy isn’t easy. If you need a long-lasting, low-maintenance solution for high-traffic or outdoor areas, Shark Coatings are your best bet. Their durability, UV resistance, and fast curing blew me away, though the higher cost might give you pause. For budget-friendly projects or indoor spaces with light use, epoxy’s affordability and DIY appeal make it a solid choice, despite its shorter lifespan and maintenance needs. Weigh your priorities—durability versus cost—and you’ll find the perfect fit.