Hey there, fellow 3D printing nerds! If you’re hunting for filament that delivers vibrant colors, reliable prints, and eco-friendly vibes, let me tell you why Polymaker filament is my go-to choice. As someone who’s spent countless hours tweaking settings and printing everything from fidget toys to functional prototypes, I’ve fallen in love with Polymaker’s quality and innovation. Whether you’re a hobbyist or a pro, this filament is a game-changer for your 3D printing adventures. Let’s dive into my experience, break down the pros and cons, compare it to other brands, and share some tips to make your prints pop!

My Experience With Polymaker Filament

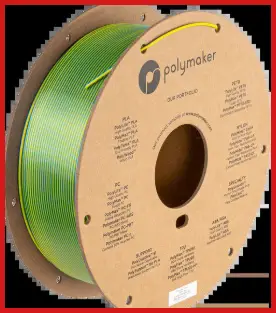

I still remember the first time I loaded a spool of Polymaker PolyLite PLA into my Creality Ender-3. The vibrant True Orange caught my eye right out of the box, and I was hooked from the first print. Over the past year, I’ve printed with their PolyLite PLA, PolyMax PLA, PolyTerra PLA, and even their Fiberon PA12-CF10 for some heavy-duty projects. Each spool felt like a new adventure, and I’ve got stories to share about what makes Polymaker stand out.

- Vibrant Colors That Pop: The colors, like True Orange and Charcoal Black PolyTerra, are rich and consistent. No washed-out hues here—just bold, eye-catching results that make my models look professional.

- Smooth Printing Experience: From the get-go, Polymaker’s filaments flowed like a dream. I had zero jams across multiple prints, even with complex designs like a multi-part whistle.

- Eco-Friendly Packaging: The cardboard spools and resealable bags won me over. It’s refreshing to see a brand care about sustainability while keeping filament fresh.

- Consistent Diameter: Polymaker’s ±0.05 mm tolerance is no joke. My prints came out smooth, with no unexpected blobs or under-extrusion issues.

- Jam-Free Technology: Their PLA uses a semi-crystalline structure that prevents softening in the hotend, reducing clogs even during long prints.

- Wide Material Variety: From PLA to PETG to nylon-based Fiberon, Polymaker’s range let me experiment with everything from decorative to industrial-grade prints.

- Community Support: Their Discord community and detailed guides helped me troubleshoot settings for PolyTerra, which was a lifesaver when I hit some stringing issues.

- Professional Finish: PolyMax PLA gave my functional parts a matte, polished look that rivals ABS, perfect for client-facing prototypes.

- Reliable Layer Adhesion: Even with Fiberon’s carbon fiber filaments, layers bonded tightly, giving my prints durability for real-world use.

- Fun Experimentation: The Panchroma line’s aesthetic options, like sparkly finishes, added a creative flair to my fidget toy designs.

Each print session with Polymaker felt like a conversation with an old friend—reliable, exciting, and full of possibilities. But it wasn’t all smooth sailing, so let’s get into the nitty-gritty of what I loved and what tripped me up.

Pros Of Polymaker Filament

Polymaker has earned its spot on my shelf for a reason. Here’s why I think you’ll love it as much as I do:

Read More: My Thought on Formlabs Vs. MakerBot

- Exceptional Print Quality: Whether it’s PolyLite or PolyMax, the surface finish is smooth and consistent. My 3DBenchy prints had crisp details with no stringing.

- Ease of Use: Even as a beginner, I found Polymaker’s PLA easy to print with default PrusaSlicer settings. No need for hours of tweaking to get started.

- Eco-Conscious Approach: PolyTerra’s cardboard spools and tree-planting initiative make me feel good about my purchases. It’s sustainability done right.

- High Strength Options: PolyMax PLA’s impact resistance is nine times that of regular PLA, making it a solid choice for functional parts like tool handles.

- Low Warping: Fiberon filaments, like PA12-CF10, have Warp-Free technology, so my large prints stayed flat without a heated chamber.

- Vivid Color Range: With colors like Cotton White and Fossil Grey, my prints always stand out. The pigments are vibrant and evenly distributed.

- Reliable Packaging: Vacuum-sealed bags with zip-locks keep filament dry, and the spools are sturdy, with holes to secure the filament end.

- Innovative Technology: Jam-Free and nano-reinforcement tech in PolyMax PLA boost print reliability and strength, setting Polymaker apart from the pack.

- Community Engagement: Polymaker’s active community on Discord and Printables offers profiles and tips, making it easy to dial in settings.

- Versatility: From flexible PolyFlex TPU to heat-resistant Fiberon PPS-CF10, there’s a filament for every project, from toys to engineering tools.

These pros make Polymaker a joy to work with, but no filament is perfect. Let’s talk about the challenges I faced.

Cons Of Polymaker Filament

While Polymaker’s filaments are top-tier, I hit a few bumps along the way. Here’s what you should watch out for:

- Higher Price Point: At $30-$60 per kg, Polymaker is pricier than budget brands like Hatchbox. My wallet felt the sting when I stocked up.

- PolyTerra Challenges: I struggled with stringing and blobbing on PolyTerra PLA until I dialed in retraction settings, which took a week of trial and error.

- Nylon Hygroscopic Issues: PolyMide CoPA absorbed moisture quickly, requiring a PolyBox or dryer, which added to my setup costs.

- Limited Color Options for Some Lines: PolyMax PLA only comes in black and white, which was a bummer for colorful projects.

- Hardened Nozzle Requirement: Fiberon filaments like PA6-CF20 are abrasive and need a hardened nozzle, which not all printers have.

- Overhang Struggles: PolyMide CoPA wasn’t great for overhangs, so I had to avoid complex designs or add supports, increasing print time.

- Temperature Demands: Fiberon PPS-CF10 requires a 310°C hotend, which my basic Ender-3 couldn’t handle without an upgrade.

- Learning Curve for Advanced Filaments: Printing with Fiberon took some research to get bed adhesion and temperatures right, which was daunting.

- PolyBox Quality Issues: My PolyBox had a loose lid, letting in some moisture. I had to add silica gel bags to keep humidity low.

- Not Ideal for High-Temperature Use: PolyMax PLA softens at 60°C, so it’s not a true ABS replacement for heat-exposed parts.

These cons didn’t ruin my experience, but they’re worth considering, especially if you’re on a budget or working with specific printers.

Maintenance And Tips To Get The Most Out Of Polymaker Filament

To make your Polymaker filament shine, a little care goes a long way. Here’s how I’ve learned to get the best results:

- Store Properly: Keep filaments in Polymaker’s resealable bags with silica gel to prevent moisture absorption, especially for nylon-based options like CoPA.

- Use a Filament Dryer: I invested in a PolyDryer ($79.99) for hygroscopic filaments. It’s a game-changer for consistent prints with PETG and nylon.

- Dial In Retraction: For PolyTerra, I tweaked retraction to 0.8 mm at 40 mm/s in PrusaSlicer to eliminate stringing. Experiment with small test prints.

- Check Nozzle Compatibility: Use a hardened nozzle for Fiberon filaments to avoid wear. I upgraded to a $15 hardened steel nozzle for PA6-CF20.

- Clean the Print Bed: Wipe your bed with isopropyl alcohol before printing to ensure adhesion, especially for PolyMax PLA’s smooth first layers.

- Adjust Temperatures: For PolyLite PLA, I used 200°C nozzle and 60°C bed. Fiberon PPS-CF10 needed 310°C, so check your printer’s limits.

- Use a PolyBox for Printing: Printing nylon in a PolyBox keeps humidity below 15%, preventing brittle prints. Add a professional hygrometer for accuracy.

- Leverage Community Profiles: Download Polymaker’s PrusaSlicer profiles from their Discord or website to save time on settings for PolySonic PLA.

- Test Small Prints First: Before tackling big projects, print a small swatch to fine-tune settings, especially for new materials like Fiberon PET-CF17.

- Post-Process with Polysher: For PolySmooth filament, use Polymaker’s Polysher to vapor-smooth prints, giving them a glossy, professional finish.

These tips turned my Polymaker prints from good to great, and I’m confident they’ll help you avoid the headaches I faced.

Comparison With Other Brands

How does Polymaker stack up against the competition? I’ve printed with Hatchbox, eSun, Overture, and Prusament, and here’s my take on how Polymaker compares.

Polymaker vs. Hatchbox

- Quality: Polymaker’s PolyLite PLA is smoother and more consistent than Hatchbox PLA, which occasionally had stringy rolls.

- Price: Hatchbox is cheaper at $20/kg vs. Polymaker’s $30/kg, making it better for budget-conscious hobbyists.

- Color Range: Polymaker offers vibrant, unique colors like True Orange, while Hatchbox sticks to standard hues.

- Ease of Use: Both are beginner-friendly, but Polymaker’s Jam-Free tech gives it an edge for clog-free printing.

- Strength: PolyMax PLA outperforms Hatchbox PLA+ in impact resistance, ideal for functional parts.

- Eco-Friendliness: Polymaker’s cardboard spools and tree-planting beat Hatchbox’s plastic spools.

- Availability: Hatchbox is easier to find on Amazon, while Polymaker requires specific retailers like MatterHackers.

- Community: Polymaker’s Discord and guides offer more support than Hatchbox’s limited resources.

- Specialty Filaments: Polymaker’s Fiberon and Panchroma lines outshine Hatchbox’s basic PLA and PETG offerings.

- Consistency: Polymaker’s tight tolerances (±0.05 mm) ensure fewer print failures compared to Hatchbox’s occasional diameter issues.

Polymaker vs. eSun

- Quality: Polymaker’s PolyLite PLA has better layer adhesion than eSun PLA+, which sometimes showed voids.

- Price: eSun is a steal at $15-$20/kg, undercutting Polymaker’s premium pricing.

- Color Options: eSun’s range is broad but less vibrant than Polymaker’s PolyTerra and Panchroma lines.

- Durability: Polymaker’s PolyMax PLA is tougher than eSun PLA+, which shattered under stress in my tests.

- Sustainability: Polymaker’s eco-friendly approach trumps eSun’s standard plastic spools.

- Ease of Printing: Both print well, but Polymaker’s Warp-Free tech reduces issues with PETG and nylon.

- Specialty Materials: Polymaker’s Fiberon composites are more advanced than eSun’s basic carbon fiber options.

- Packaging: Polymaker’s vacuum-sealed, resealable bags keep filament fresher than eSun’s basic packaging.

- Support: Polymaker’s community resources outshine eSun’s limited documentation.

- Reliability: eSun had occasional sealing issues, while Polymaker’s spools were flawless in my experience.

Polymaker vs. Overture

- Quality: Polymaker’s finish is glossier and more consistent than Overture PLA, which had matte surprises.

- Price: Overture’s $18-$22/kg price point is more wallet-friendly than Polymaker’s $30-$60/kg.

- Color Vibrancy: Polymaker’s colors pop more than Overture’s, which can look muted.

- Strength: PolyMax PLA’s nano-reinforcement beats Overture PLA+ for durability in functional prints.

- Eco-Friendliness: Polymaker’s sustainable spools outshine Overture’s plastic ones.

- Ease of Use: Both are easy, but Polymaker’s tech reduces clogs compared to Overture’s occasional jams.

- Range: Polymaker’s Fiberon and PolySonic lines offer more variety than Overture’s standard offerings.

- Community: Polymaker’s active Discord community gives it an edge over Overture’s minimal support.

- Packaging: Polymaker’s resealable bags are superior to Overture’s basic vacuum seals.

- Consistency: Polymaker’s tight tolerances win over Overture’s occasional diameter variations.

Polymaker vs. Prusament

- Quality: Both deliver top-notch prints, but Polymaker’s PolyMax PLA edges out Prusament PLA for strength.

- Price: Prusament’s $25-$30/kg is competitive, but Polymaker’s specialty filaments are pricier.

- Color Options: Prusament’s colors are vibrant, but Polymaker’s Panchroma line adds unique aesthetic flair.

- Ease of Printing: Both are plug-and-play, though Polymaker’s Jam-Free tech reduces hotend issues.

- Strength: PolyMax PLA’s impact resistance surpasses Prusament PLA, which is more brittle.

- Eco-Friendliness: Polymaker’s cardboard spools beat Prusament’s plastic ones for sustainability.

- Availability: Prusament is Prusa-exclusive, while Polymaker is widely available through resellers.

- Support: Both have strong communities, but Polymaker’s Discord is more accessible than Prusa’s forums.

- Specialty Filaments: Polymaker’s Fiberon and PolyMide lines offer more engineering options than Prusament.

- Packaging: Polymaker’s resealable bags match Prusament’s high-quality packaging standards.

Polymaker holds its own against these brands, offering a premium experience with a focus on innovation and sustainability, though its price can be a hurdle for some.

Frequently Asked Questions (Faq)

Polymaker is indeed based in Shanghai, China, with its headquarters at Changshu Innopark. Founded in 2013 by a team with PhDs in polymer science, they’ve built a global reputation with offices and distribution worldwide, including in the US. Their focus on quality control and innovation makes them a standout, regardless of their origin.

Polymaker’s filaments vary in strength depending on the type. PolyMax PLA boasts a Charpy impact strength of 12.2 ± 1.03 kJ/m², nine times stronger than standard PLA and 20% tougher than ABS. Fiberon PA6-CF20 and PA12-CF10 offer excellent mechanical properties for industrial use, with high stiffness and heat resistance. Even PolyLite PLA has solid layer adhesion, holding up to 57 MPa in tensile tests.

No, Polymaker filament is manufactured in China, where their production facilities are located. They maintain strict quality control, which contributes to their consistent performance. While they have a US presence through distributors like MatterHackers, the actual production happens in Shanghai.

Polymaker offers vibrant colors, easy printing with Jam-Free technology, and high-strength options like PolyMax and Fiberon for functional parts. Their eco-friendly cardboard spools and tree-planting initiative appeal to sustainability lovers. Tight tolerances (±0.05 mm) ensure reliable prints, and their community support helps you troubleshoot. Plus, their wide range of materials, from PLA to nylon, suits any project.

Conclusion

Read More: My Thought on Formlabs Vs. MakerBot

If you’re ready to elevate your 3D printing game, Polymaker filament is the way to go. Its vibrant colors, reliable performance, and eco-friendly ethos make every print a joy. From PolyLite’s ease to PolyMax’s strength, there’s something for every maker. Trust me, once you try Polymaker, you’ll wonder why you settled for less. Grab a spool, tweak those settings, and let your creativity soar!