When you’re ready to jump into the world of 3D printing or even upgrade your existing setup, the Bambu Lab A1 is one of those products that keeps popping up. If you’re wondering where you should buy this exceptional piece of machinery, I highly recommend checking out the official Bambu Lab website first for the best bundle deals, especially the one that includes the AMS Lite for multi-color printing.

Additionally, authorized retailers like Micro Center often carry them, which is a great option if you prefer an in-person purchase experience. This review is my personal, in-depth look at the A1, a machine that has truly reshaped my perception of what an affordable 3D printer can accomplish.

My Experience With Bambu Lab A1

When the Bambu Lab A1 first arrived at my doorstep, I was a seasoned hobbyist but one who was frankly tired of the endless tinkering that defined the ‘budget’ 3D printer landscape. My previous printer—a popular bedslinger from a competing brand—felt like a constant project, requiring manual calibration, firmware flashes, and endless adjustments just to get a decent, consistent print. Honestly, it often felt more like an assembly and maintenance chore than a creative hobby. The A1 was supposed to be different. It promised “just work” functionality, high speed, and excellent quality right out of the box, and I was skeptical but hopeful.

The setup process was the first shock.

I’m used to spending an entire evening assembling a 3D printer from a box of parts.

With the A1, it was a matter of minutes.

The gantry slides onto the base, a few screws go in, and a couple of wires are plugged in, following the clear, concise instructions on the screen.

The entire process, from unboxing to turning it on, took less than half an hour.

That alone was a monumental shift. Then came the magical moment: the automatic calibration. Instead of me fumbling with feeler gauges or agonizing over mesh bed leveling numbers, the A1 took over. It ran its automatic bed leveling, vibration compensation, and flow calibration. It wasn’t a quick, superficial check; it was a thorough, multi-step process that made me feel like the machine was truly preparing itself for perfection.

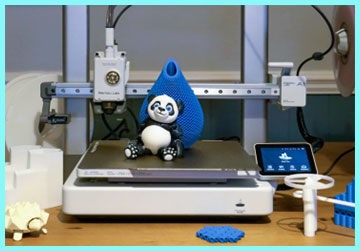

My first print was the famous benchy—a benchmark boat model. On my old machine, this print was a nerve-wracking 3-hour affair, hoping the supports didn’t fail and the layers didn’t shift. On the A1, I hit print via the app, watched the progress on the built-in camera, and had a high-quality benchy in my hands in under 40 minutes, completely flawless and with layers so uniform you could barely distinguish them. I didn’t tweak a single setting. That’s when the true value proposition of the A1 hit me: it respects your time. It transforms 3D printing from an exercise in patience and troubleshooting into a tool for immediate creation.

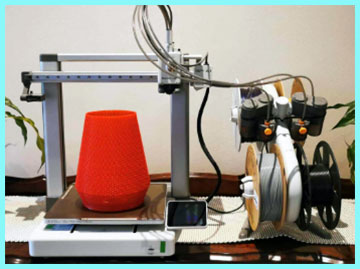

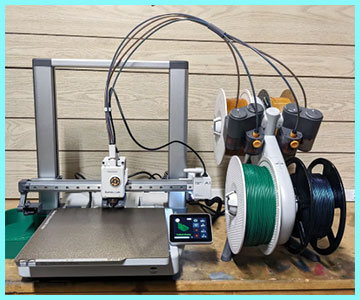

I opted for the Combo package with the AMS Lite, and that’s where the fun really began. Multi-color printing used to be reserved for expensive, high-end machines or painstaking manual filament swaps. The AMS Lite—that funky, external material station—made four-color printing as simple as loading four spools and assigning colors in the Bambu Studio slicer. I started printing models I’d only ever dreamed of: multi-colored figurines, functional parts with different colored labels, and intricate organizational boxes. Yes, there’s purge waste, which is a common trade-off for multi-color FDM, but the sheer ease of getting those vibrant, complex prints was intoxicating. I spent less time staring at progress bars and more time designing or simply watching the machine work its fast, precise magic.

The machine’s speed is exhilarating. It handles rapid movements and acceleration with impressive stability, largely thanks to its active vibration compensation. It’s a bedslinger design, which traditionally struggles at high speeds compared to CoreXY printers, but the A1’s engineering mitigates this beautifully. I’ve pushed it, printing at its maximum rated speeds, and the quality dip is surprisingly minimal. For rapid prototyping or printing utility parts, this speed is a game-changer.

It makes you realize how much potential time was wasted waiting for slower machines. The user experience, from the responsive touch screen to the seamless integration with the Bambu Handy mobile app and the Bambu Studio slicer, is meticulously polished. It feels like using a modern consumer electronic device, not a specialized piece of industrial equipment, and that accessibility is its greatest triumph. I genuinely feel like this machine liberated my creativity by eliminating the technical friction.

Read More: Comparison Of Flashforge Vs. Toybox 3D Printer

Pros Of Bambu Lab A1

- Exceptional Speed and Print Quality Out of the Box: The A1 is genuinely fast, achieving speeds up to 500 mm/s. What impressed me most wasn’t just the raw speed, but that this speed is paired with consistently high-quality prints right from the moment you turn it on. You don’t have to spend hours tweaking slicer settings or printer firmware; it just works, delivering smooth surfaces and accurate dimensions on the default profile.

- Fully Automatic Calibration System: This feature is a massive time saver and stress reliever. The automatic bed leveling, active vibration compensation, and, most importantly, the automatic flow calibration using the eddy current sensor, mean you never have to manually adjust critical settings. The printer does its own health check before every print, which translates to a vastly reduced failure rate for me.

- Optional Multi-Color/Multi-Material Printing with AMS Lite: The ability to print with up to four different colors or materials using the external AMS Lite is revolutionary at this price point. It’s an incredibly accessible way to achieve complex, visually striking prints, transforming the aesthetic possibilities of FDM printing for the average user like myself.

- Quick-Swap Nozzle System: No more wrestling with tiny wrenches and worrying about stripping threads on a hot nozzle. The A1’s quick-swap hotend assembly is brilliant, allowing me to change nozzle sizes (from a fine 0.2mm to a chunky 0.8mm) in literally seconds with one click, making maintenance and material changes incredibly fast and simple.

- Intuitive Software Ecosystem (Bambu Studio & Bambu Handy): The dedicated slicer, Bambu Studio, is powerful, fast, and pre-configured for the A1, removing the guesswork. Furthermore, the Bambu Handy mobile app allows me to monitor my prints remotely via the built-in camera, start or stop prints, and even get notifications on my phone, making the entire printing process highly convenient.

- Solid Build Quality for a Bedslinger Design: While it’s a bedslinger (Cartesian design), the overall construction is robust, featuring high-quality components and linear bearings on the X and Z axes, which helps it maintain precision and minimize resonance artifacts even at high speeds. It feels like a premium machine despite its relatively budget-friendly position in the Bambu Lab lineup.

- Integrated Monitoring Camera and Time-Lapse Functionality: The built-in camera is a feature I didn’t think I’d care much about, but it has become indispensable. It allows me to check on prints remotely and automatically creates stunning, smooth time-lapse videos of my prints, which is a fun way to document my projects.

- Excellent Filament Compatibility and Handling: The direct-drive extruder handles flexible materials like TPU exceptionally well. The printer is designed to work seamlessly with a wide range of common filaments, including PLA, PETG, TPU, and PVA, without constant tweaking, which opens up many creative and functional applications.

Cons Of Bambu Lab A1

- Open-Frame Design Lacks Enclosure for Advanced Filaments: The A1 is an open-frame bedslinger printer. The lack of an enclosed build chamber: This means printing high-temperature, warp-prone materials like ABS, ASA, or Nylon is challenging, if not impossible, without a separate, custom enclosure, limiting its versatility for engineering-grade prints.

- Proprietary Ecosystem and Cloud Dependence: While the seamless software is a pro, it comes with a trade-off. The system is largely tied into the Bambu Lab ecosystem: This means relying on their proprietary slicer and, often, their cloud service for remote printing and monitoring, which can be a drawback for users who prioritize open-source solutions or prefer to operate entirely offline for privacy or network reasons.

- The Multi-Color Printing Generates Significant Filament Waste (Purge): The AMS Lite is fantastic, but the mechanism for multi-color printing requires purging the old color before introducing the new one. This purging process generates a noticeable ‘poop’ chute of waste material: For small prints or prints with frequent color changes, the amount of wasted plastic can sometimes be equivalent to or even exceed the amount of plastic in the final print, which feels wasteful.

- Bedslinger Design Inherently Limits Maximum Performance: Although Bambu Lab has done an incredible job mitigating the issues, the Cartesian (bedslinger) design still means the moving bed adds inertia. The printer cannot achieve the absolute highest speeds and artifact suppression of the more expensive CoreXY models: This is a fundamental mechanical limitation, meaning it’s fast for a bedslinger, but not the fastest overall.

- Initial Batch Heatbed Cable Recall Issue: An issue was identified in an initial production batch concerning the heatbed cable potentially becoming damaged, which could pose a fire or shock hazard. While Bambu Lab handled the recall proactively with clear options for refund or repair: This incident did cause a period of user concern and highlights that even high-tech printers can have significant hardware flaws.

- Higher Entry Price Point Compared to Basic Bedslingers: While it’s an affordable printer for its features, it’s still priced higher than the absolute cheapest entry-level bedslingers on the market. The cost barrier is higher for a complete beginner on an extremely tight budget: The “combo” version with the AMS Lite pushes the price into a mid-range category, which might deter some first-time buyers.

- Noise Level is Noticeable at Maximum Speed: When operating at its highest speeds, especially during the vibration compensation routine, the printer generates a significant amount of noise. The sound levels can be disruptive in a quiet home or office environment: While it has a quiet mode, using it often means sacrificing some of that hallmark speed.

Maintenance Tips For Bambu Lab A1

Maintaining the Bambu Lab A1 is refreshingly simple compared to my past experiences, largely due to its advanced engineering, but a few simple routines will keep it performing flawlessly. Remember, consistency is key!

- Regular Build Plate Cleaning is Essential: A clean build plate is the single most important factor for good first-layer adhesion. Always clean your textured or smooth PEI plate with warm water and dish soap (like Dawn or a similar grease-cutting brand): Do this about once a month, or whenever you notice adhesion issues. Between washes, a quick wipe down with isopropyl alcohol is great, but don’t rely on alcohol alone, as it can sometimes spread residual grease instead of removing it.

- Lubrication of Guide Rails and Lead Screws: The A1 has a recommended maintenance schedule you should follow, often prompted by the machine itself. After every 100 printing hours, the printer may prompt you to lubricate the axis rails and lead screws: Use the official Bambu Lab lubricant (or a suitable alternative like a good quality grease or oil for linear rails/bearings) sparingly. Clean the rails first with a lint-free cloth, apply a small amount of lubricant, and then manually move the print head and bed along the axes to distribute it evenly.

- Keep the Extruder Gear Clean: Filament dust and debris can accumulate on the extruder gears over time, leading to inconsistent extrusion or even clogs. Clean the extruder gear after every 5-10 spools of non-abrasive filament (more often for carbon fiber/wood-filled filaments): You can often access the gears to brush them clean with a small, soft brush or use a blast of compressed air to remove loose debris, preventing slippage.

- Periodic Inspection of the Heatbed Cable and Movement: This is especially important for early batch users, but good practice for everyone. Visually inspect the heatbed cable that moves with the print bed regularly: Ensure it isn’t sharply bent, pinched, or showing any signs of wear or damage to the insulation, as a faulty cable was the cause of the previous recall issue. Also, ensure the bed moves smoothly without excessive resistance.

- Clean and Check the Nozzle/Hotend Assembly: Even with the quick-swap feature, the nozzle can still get clogged, especially after using different material types. Perform a ‘cold pull’ to clear minor clogs, or use the needle included with the printer to clear filament from the hotend: Always do this when the hotend is heated to the material’s melting temperature. If the clog is persistent, the quick-swap makes it easy to replace the entire hotend module.

- Tensioning of Belts (X and Y-Axis): While the A1 is generally very well-tuned, belt tension can loosen slightly over many hours of printing, which can lead to print artifacts like ghosting or ringing. Check the belt tension if you start seeing recurring wavy patterns or inaccurate dimensions: The machine can prompt you to check this, and the process involves slightly loosening a tension screw, moving the carriage, and re-tightening, as outlined in the official wiki guides.

- Filament Sensor and Wiper Cleaning: The A1 has a filament run-out sensor and an extruder wiper that are critical for its automated functions. Occasionally clean the filament sensor path and the purge wiper near the heatbed: Use compressed air or a fine brush to ensure no filament dust or small pieces are obstructing the sensors or the movement of the wiper, which can cause false alarms or poor purging.

Comparison With Other Brands

When you look at the 3D printing market, the Bambu Lab A1 sits in a fascinating and highly competitive space, often forcing comparisons to long-standing industry giants and newer high-speed entrants.

Versus the Prusa MK4

The Prusa MK4 represents the pinnacle of reliability and open-source excellence, a well-established heritage in the industry. The MK4 is often viewed as the more robust, ‘built-to-last’ machine with a fully open-source hardware and software philosophy: This appeals to tinkerers and those who value the ability to repair, modify, and completely control their machine without relying on a manufacturer’s closed ecosystem. The A1, however, beats the MK4 on pure speed, offering a significantly faster printing experience for standard materials. Furthermore, the A1’s seamless, plug-and-play experience and its optional multi-color system (AMS Lite) are far more user-friendly and feature-rich than the MK4’s multi-material upgrade (MMU3), which is notoriously more complex to set up and maintain. While the MK4 costs substantially more, its high-quality components and long-term community support are its major selling points, whereas the A1’s value proposition is its combination of speed, quality, and low price.

Versus the Creality K1 Series

The Creality K1 and its variants are Bambu Lab’s most direct competition in the “high-speed, affordable” category. The K1 employs the CoreXY motion system, which is mechanically superior for speed and stability compared to the A1’s bedslinger design: This means the K1 theoretically has a higher ceiling for speed and print quality at those speeds because its build plate only moves in the Z-axis. However, my experience is that the A1, while a bedslinger, often provides a more consistent and reliable high-speed experience right out of the box due to Bambu Lab’s superior software and quality control. The K1, particularly at launch, required much more user tinkering and firmware updates to achieve its potential, a contrast to the A1’s ready-to-print nature. The A1 also features a much larger build volume than the standard K1, and its AMS Lite provides a multi-color solution that is generally perceived as much simpler and more effective than any comparable Creality system for the A1’s price point.

Versus Traditional Budget Bedslingers (e.g., Ender 3 V3 KE)

When comparing the A1 to the older generation of budget-friendly Cartesian printers or even their modern, updated successors, the difference is stark. The traditional budget printers, while incredibly cheap, require substantial effort in assembly, manual calibration, and often immediate component upgrades to achieve the quality and speed of the A1: These older machines are essentially a platform for learning and modification, a hobby in themselves. The A1 is a finished consumer product; it’s faster, smarter, and delivers better results without the need for constant hands-on effort. You pay a premium for the A1, but you save countless hours of troubleshooting and manual adjustment, essentially buying a reliable tool instead of a project. The integrated features like the camera, automatic calibration, and polished software suite are features that would cost a user hundreds of dollars and many hours to add to a budget-level competitor.

Also Read: Comparison Of Flashforge Vs. Prusa 3D Printers

Frequently Asked Questions (FAQ)

The most common issues users report tend to revolve around filament-related matters, such as stringing or poor layer adhesion, which are often a result of using wet filament and not drying it properly, or needing to adjust specific material profiles. Another frequent, though minor, issue is the accumulation of purge material (“poop”) when using the AMS Lite for multi-color printing, which requires regular cleanup. Finally, like all bedslingers, vibrations at extremely high speeds can sometimes lead to slight artifacts, though this is largely minimized by the active compensation.

From my perspective, and the general consensus in the 3D printing community, yes, Bambu Lab printers are really that good, particularly in terms of user experience and out-of-the-box performance. They essentially set a new standard by delivering high-speed, high-quality printing with minimal required user intervention or tinkering. They successfully transformed 3D printing from a complex hobby into an accessible consumer tool, thanks to features like fully automatic calibration and seamless software integration.

The primary controversy surrounding Bambu Lab stems from their closed-source ecosystem (unlike many long-standing competitors) and the initial heatbed cable recall of the A1. The closed-source nature concerns some users who prefer transparency and the freedom to modify and repair their printers with community-developed software. The recall, while handled well by the company, involved a serious hardware defect that could pose electric shock and fire hazards in early models, leading to a temporary halt in sales and a major replacement/refund program.

The Bambu Lab A1 was recalled in early 2024 because of a potential safety hazard related to the heatbed cable. It was discovered that the heatbed cable in early production units could become damaged if bent excessively during shipping or as installed. This damage could lead to a short circuit, which posed a risk of electric shock or fire. Bambu Lab subsequently offered all affected customers a choice between a full refund upon return or a free replacement of the entire heatbed and cable assembly.

Conclusion: For Bambu Lab A1

The Bambu Lab A1 is a revolutionary 3D printer that has completely altered the landscape for hobbyists and professionals alike. Its potent combination of blistering speed, superb out-of-the-box print quality, and the unparalleled accessibility of multi-color printing via the AMS Lite makes it, in my opinion, the single best value proposition currently available. While the recall was a setback and the bedslinger design has limitations, the A1 succeeds brilliantly in its goal: removing the friction from 3D printing and letting your creativity flow without endless calibration headaches. If you value your time and seek high-quality results with effortless operation, you owe it to yourself to consider the A1—it is a game-changer you won’t regret buying.