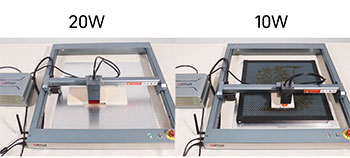

Laser engraving has become increasingly popular among hobbyists, artists, and small business owners. Whether you’re looking to personalize gifts, create custom designs, or start a side hustle, choosing the right laser engraver is crucial.

Two popular options on the market are 10W and 20W laser engravers. But which one should you choose? Let’s dive into the world of laser engraving and explore the differences between these two power levels.

Comparison Table

| Feature | 10W Laser Engraver | 20W Laser Engraver |

| Cutting Depth | Up to 3mm | Up to 6mm |

| Engraving Speed | Moderate | Fast |

| Material Versatility | Good | Excellent |

| Price | More affordable | Higher initial cost |

| Power Consumption | Lower | Higher |

| Learning Curve | Easier for beginners | Steeper learning curve |

| Ideal Use | Hobbyists, occasional use | Frequent users, small businesses |

| Smoke Production | Less | More |

| Maintenance | Less frequent | More frequent |

| Safety Considerations | Lower risk | Higher risk, more precautions needed |

Now that we’ve got a quick overview, let’s delve deeper into the world of laser engraving and explore the pros and cons of both 10W and 20W laser engravers.

Understanding Laser Engraver Power

Before we jump into the specifics of 10W and 20W laser engravers, it’s important to understand what these numbers mean. The wattage of a laser engraver refers to the power output of the laser beam. In simple terms, the higher the wattage, the more powerful the laser.

But power isn’t everything. It’s like comparing a sports car to a family sedan. Sure, the sports car has more horsepower, but that doesn’t necessarily make it the best choice for everyone. The same principle applies to laser engravers.

10W Laser Engraver: The Nimble Newcomer

Pros of 10W Laser Engravers

- Affordability: Let’s face it, we all love a good deal. 10W laser engravers are generally more budget-friendly, making them an attractive option for hobbyists or those just dipping their toes into the laser engraving world.

- Compact Size: These machines often come in smaller packages, perfect for those of us who don’t have a dedicated workshop. You could easily set one up on your desk without feeling like you’re running a factory in your spare room.

- Lower Power Consumption: With great power comes great electricity bills. 10W engravers are more energy-efficient, which means you can engrave to your heart’s content without worrying about skyrocketing utility costs.

- Safer for Beginners: While all laser engravers require safety precautions, 10W models are generally considered safer for newcomers. It’s like learning to drive on a sedan before hopping into a race car.

- Suitable for Delicate Materials: If you’re working with materials that are sensitive to heat, like certain plastics or thin woods, a 10W laser provides enough power without risking damage to your workpiece.

Cons of 10W Laser Engravers

- Limited Cutting Depth: While 10W lasers can handle engraving on various materials, they struggle with deeper cuts. Think of it as trying to cut a thick steak with a butter knife – it’ll work, but it’s not ideal.

- Slower Engraving Speed: If time is money, then 10W engravers might cost you in the long run. They generally work slower than their more powerful counterparts, which can be frustrating if you’re trying to complete large projects or multiple orders.

- Less Versatile: While 10W lasers can handle many materials, they may struggle with harder substances like thick leather or dense woods. It’s like having a Swiss Army knife without the corkscrew – useful for many things, but not everything.

- May Require Multiple Passes: For deeper engravings or cuts, you might need to run your 10W laser over the same area multiple times. This not only slows down your work but can also lead to inconsistencies in the final product.

- Limited for Professional Use: If you’re planning to start a business or scale up your production, a 10W laser might leave you wanting more. It’s great for personal projects, but may not keep up with higher demands.

20W Laser Engraver: The Powerful Performer

Pros of 20W Laser Engravers

- Increased Cutting Depth: With a 20W laser, you’re stepping up your game. These machines can cut through thicker materials, opening up a world of possibilities for your projects. It’s like upgrading from a butter knife to a chef’s knife.

- Faster Engraving Speed: Time is precious, and 20W lasers respect that. They can zip through projects much quicker than their 10W counterparts, which is a huge plus if you’re running a business or have a long queue of projects.

- Versatility: From wood to leather, acrylic to some metals, 20W lasers can handle a wider range of materials. It’s like having a fully-equipped Swiss Army knife – you’re prepared for almost anything.

- Better for Professional Use: If you’re serious about laser engraving as a business, a 20W machine gives you the power and speed to meet customer demands and maintain quality.

- Cleaner Cuts and Engravings: The increased power often results in crisper lines and cleaner cuts. It’s the difference between a child’s crayon drawing and a fine-line pen sketch.

Cons of 20W Laser Engravers

- Higher Initial Cost: Quality comes at a price, and 20W laser engravers are generally more expensive than 10W models. It’s an investment, much like buying a high-end camera instead of a point-and-shoot.

- Increased Power Consumption: With great power comes great electricity bills (yes, I’m repeating myself, but it’s true!). 20W lasers will use more energy, which is something to consider if you’re watching your utility costs.

- Steeper Learning Curve: More power means more variables to control. Getting the settings just right on a 20W laser can be trickier, especially for beginners. It’s like jumping from an automatic car to a manual – there’s more to manage.

- Safety Considerations: While all laser engravers require safety precautions, the higher power of 20W lasers means you need to be extra vigilant. Proper eye protection, ventilation, and fire safety measures are crucial.

- Overkill for Some Projects: If you’re mainly working on simple, thin materials, a 20W laser might be more than you need. It’s like using a sledgehammer to hang a picture frame – effective, but unnecessary.

Real-World Applications: Putting Theory into Practice

Now that we’ve covered the pros and cons, let’s look at how these differences play out in real-world scenarios. After all, theory is great, but practical application is where the rubber meets the road (or in this case, where the laser meets the material).

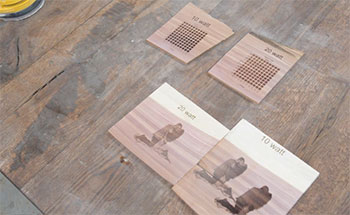

Engraving on Wood

Wood is a popular material for laser engraving, and both 10W and 20W lasers can handle it. However, the results and process can vary significantly.

With a 10W laser, you can easily engrave on softer woods like pine or balsa. The lower power is gentle enough to create detailed designs without burning through the material. However, for harder woods like oak or maple, you might find yourself making multiple passes to achieve the desired depth. It’s like slowly sanding down a surface – it takes time, but you have more control.

A 20W laser, on the other hand, can tackle harder woods with ease. The increased power means you can achieve deeper engravings in a single pass, saving time and ensuring consistency. It’s particularly useful for creating signs or intricate wooden art pieces. However, you’ll need to be more careful with power settings to avoid scorching or burning the wood.

Cutting Acrylic

Acrylic is another popular material in the laser engraving world, used for everything from signage to jewelry. Here’s where the difference between 10W and 20W lasers becomes more pronounced.

A 10W laser can certainly cut acrylic, but it’s limited in terms of thickness. You’re looking at a maximum of about 3mm, and even that might require multiple passes. It’s like trying to cut a thick piece of cheese with a butter knife – doable, but not ideal.

With a 20W laser, you can cut acrylic up to 6mm thick in a single pass. This opens up possibilities for creating more substantial pieces, like standees or 3D structures. The cuts are also cleaner, with less melting along the edges. It’s like using a hot knife through butter – smooth and efficient.

Leather Engraving

Leather is a tricky material that requires a delicate touch. Both 10W and 20W lasers can engrave leather, but the approach and results differ.

A 10W laser is often preferred for delicate leather work. The lower power allows for more control, reducing the risk of burning or discoloring the leather. It’s perfect for creating subtle designs on wallets, belts, or book covers. Think of it as using a fine-tipped marker instead of a thick Sharpie.

A 20W laser, while more powerful, can still be used effectively on leather with the right settings. It excels at cutting leather, allowing you to create intricate patterns or even cut out entire shapes. However, you’ll need to be more careful with power and speed settings to avoid damage. It’s like using a very sharp knife – incredibly effective, but requiring a steady hand.

Metal Marking

When it comes to metal, the difference between 10W and 20W lasers becomes even more apparent.

A 10W laser can mark some metals, but it’s limited. You might be able to create a surface discoloration on aluminum or stainless steel, but don’t expect deep engravings. It’s like trying to write on a whiteboard with a nearly dried-out marker – you can see something, but it’s not very impressive.

A 20W laser, while still not powerful enough for deep metal engraving, can create more visible and lasting marks on a wider range of metals. With the right coatings or techniques, you can achieve more professional-looking results on items like tools, jewelry, or industrial parts. It’s more like using a permanent marker – the results are clearer and more durable.

The Learning Curve: Mastering Your Machine

Regardless of whether you choose a 10W or 20W laser engraver, there’s going to be a learning curve. It’s like picking up any new skill – it takes time, patience, and a willingness to make (and learn from) mistakes.

With a 10W laser, the learning curve is generally gentler. The lower power means there’s less risk of damaging materials as you figure out the right settings. It’s forgiving, allowing you to experiment without too much worry. Think of it as learning to cook with a slow cooker – it’s hard to burn your food, even if you’re not quite sure what you’re doing.

A 20W laser, while more powerful and versatile, requires a bit more finesse. You’ll need to spend more time understanding how different power levels and speeds affect various materials. It’s like learning to cook on a gas stove – more control, but also more ways to accidentally char your dinner.

However, don’t let this deter you from a 20W laser if that’s what you need. The steeper learning curve comes with the reward of greater capabilities once you’ve mastered it. It’s an investment in your skills as well as your equipment.

Maintenance Matters: Keeping Your Laser in Top Shape

Maintenance is a crucial aspect of owning a laser engraver, regardless of its power. However, the requirements can differ between 10W and 20W models.

10W lasers, being less powerful, generally require less intensive maintenance. They produce less heat and smoke, which means less buildup of residue on the lens and mirrors. It’s like owning a bicycle instead of a car – regular cleaning and occasional adjustments are usually enough to keep it running smoothly.

20W lasers, on the other hand, may need more frequent attention. The higher power means more heat generation and potentially more smoke and debris, especially if you’re cutting materials rather than just engraving. You’ll need to clean the lens and mirrors more often and be more vigilant about checking alignments. It’s more akin to maintaining a car – regular servicing is essential to keep it performing at its best.

FAQs

The choice between a 10W and 20W laser engraver depends on your specific needs and goals. If you’re a hobbyist or just starting out, a 10W laser engraver might be sufficient. It’s more affordable, easier to learn, and can handle a variety of materials for light engraving and cutting.

However, if you’re planning to start a business, work with thicker or harder materials, or need faster engraving speeds, a 20W laser engraver might be a better choice. It offers more power, faster speeds, and greater versatility, allowing you to take on a wider range of projects.

Consider factors like the types of materials you’ll be working with most often, the volume of work you plan to do, and your budget. Remember, it’s often better to invest in a machine that can grow with your skills and needs rather than one you might outgrow quickly.

A 20W laser engraver is capable of cutting through a variety of materials, including:

Wood: Up to 6mm thick, depending on the type of wood.

Acrylic: Up to 6mm thick in a single pass.

Leather: Can cut through most types of leather, even thick leather up to 3-4mm.

Fabric: Easily cuts through most fabrics, including denim and canvas.

Paper and Cardboard: Cuts cleanly through multiple layers.

Thin plastics: Can cut through many types of thin plastics.

Cork: Easily cuts through cork sheets.

Foam: Cuts through various types of craft foam.

It’s important to note that while a 20W laser can cut these materials, the exact thickness it can handle may vary based on the specific material properties and the laser engraver model. Always refer to your machine’s specifications and conduct tests before attempting large projects.

The best wattage for laser engraving depends on your specific needs, but for most hobbyists and small businesses, lasers in the 10W to 20W range are often sufficient. Here’s a general guide:

5-10W: Good for light engraving on softer materials like wood, leather, and some plastics. Suitable for hobbyists and occasional users.

10-20W: Versatile range suitable for most hobbyists and small businesses. Can handle engraving and light cutting on a wide range of materials.

20-40W: Ideal for more professional use, faster engraving speeds, and the ability to cut thicker materials.

40W+: Suited for industrial applications, very thick materials, or high-volume production.

For most users, a 10W to 20W laser engraver provides a good balance of power, versatility, and cost. It allows you to tackle a wide range of projects without the higher cost and increased safety considerations of more powerful lasers.

A 20 watt laser engraver can typically cut through wood up to about 6mm (1/4 inch) thick, depending on the type of wood and the specific laser engraver model. However, this can vary based on several factors:

Wood Type: Softer woods like pine or balsa can be cut more easily and to greater depths than harder woods like oak or maple. You might be able to cut slightly thicker soft woods, while harder woods may limit you to thinner pieces.

Laser Focus: A well-focused laser beam will cut more efficiently than a poorly focused one. Proper focus is crucial for achieving maximum cutting depth.

Number of Passes: While a single pass might cut through 3-4mm of wood, multiple passes can allow you to cut thicker pieces. However, this takes more time and may result in more charring along the cut edges.

Cutting Speed: Slower speeds generally allow for deeper cuts, but too slow can cause excessive burning.

Wood Moisture Content: Drier wood is generally easier to cut than wood with higher moisture content.

Laser Engraver Quality: The quality and efficiency of the laser engraver itself can affect cutting depth. Some 20W lasers may perform better than others due to differences in design and components.

It’s important to note that while a 20W laser can theoretically cut wood up to 6mm thick, for best results and clean cuts, it’s often recommended to stick to wood that’s 3-4mm thick or less. For thicker pieces, you might need to make multiple passes or consider a more powerful laser.

Always remember to test on scrap material first and adjust your settings as needed. Safety should always be your top priority when operating any laser engraving equipment.

Also Read: 1080p Vs. 2.5K: The Ultimate Resolution Showdown

The Bottom Line: Making Your Choice

So, after all this, which should you choose – a 10W or 20W laser engraver? The answer, as with many things in life, is: it depends.

If you’re a hobbyist, just starting out, or primarily working with thinner, softer materials, a 10W laser engraver might be perfect for you. It’s more affordable, easier to learn, and still capable of producing beautiful results on many materials. It’s like choosing a point-and-shoot camera – great for learning the basics and capturing memories, even if it doesn’t have all the bells and whistles.

On the other hand, if you’re looking to start a business, work with a wide range of materials, or need to produce results quickly, a 20W laser engraver could be worth the investment. The increased power and speed can help you take on more ambitious projects and handle larger volumes of work. It’s like choosing a DSLR camera – more complex, but capable of professional-quality results in the right hands.

Remember, the best tool is the one that fits your specific needs and skill level. Consider what materials you’ll be working with most often, how quickly you need to complete projects, and what your long-term goals are. And don’t forget to factor in ongoing costs like maintenance and power consumption.

Whichever you choose, remember that the machine is just a tool. The real magic comes from your creativity and willingness to learn and experiment. Whether you’re wielding 10 watts or 20, the possibilities are limited only by your imagination. So choose your laser, fire it up, and start creating!